Neck Block Shift

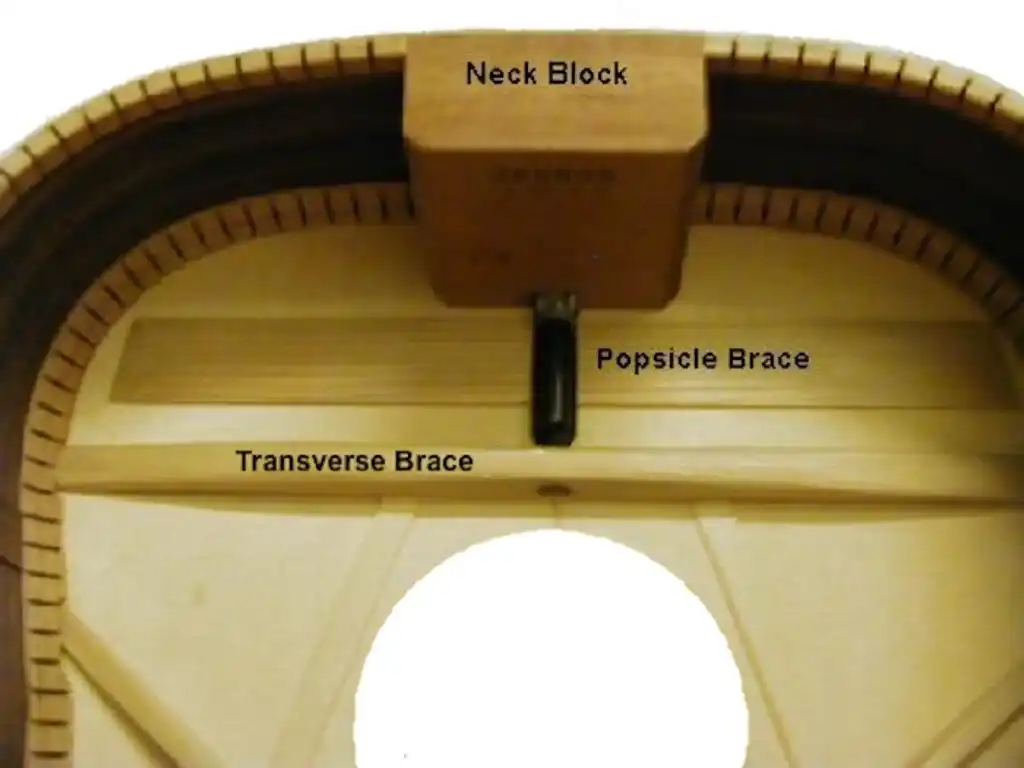

The neck block may be the single-most critical component of the acoustic guitar, likened to the "cornerstone" of the building or the "hub" of the spoked wheel. It is the structural intersection of the back, sides, soundboard and neck. The primary force acting upon the neck block is the result of the constant pull of the strings. The strings are (typically) anchored to a bridge which is glued to the soundboard. Each string is secured to a tuning machine head which, in turn, is secured to the headstock at the end of the neck. The neck is traditionally attached to the neck block using a woodworking joint known as a compound dovetail, though it may also be attached with dowels, loose tenons or even bolts.

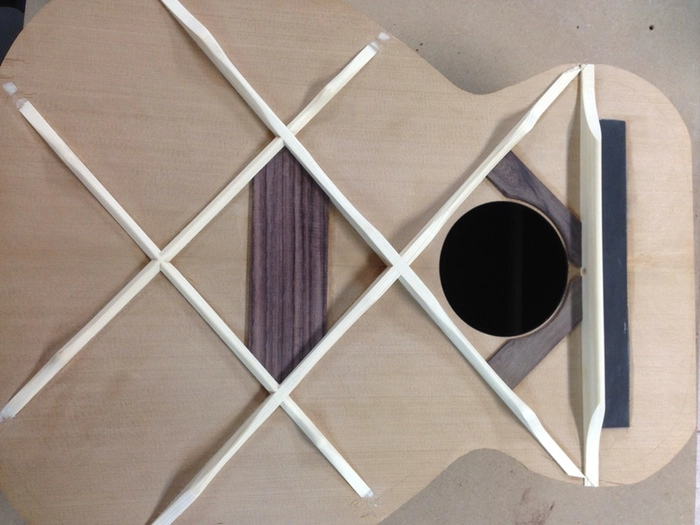

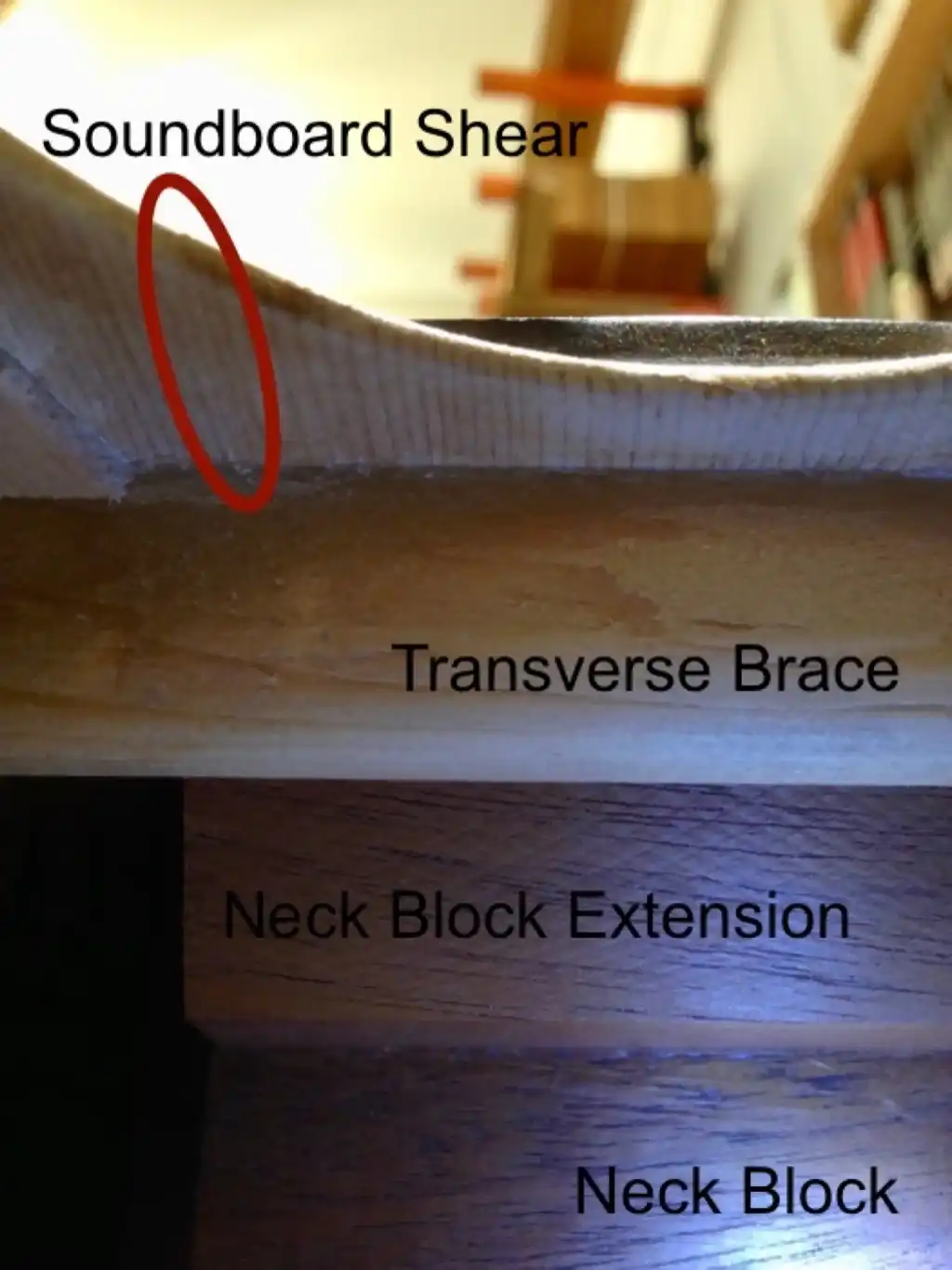

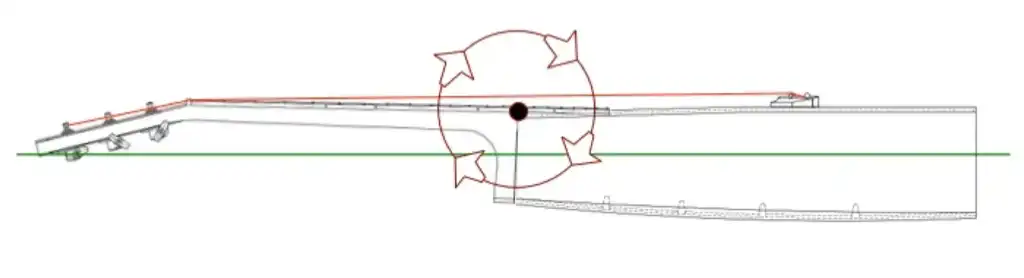

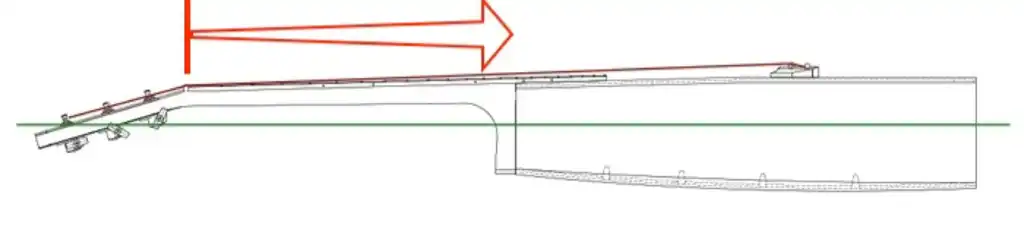

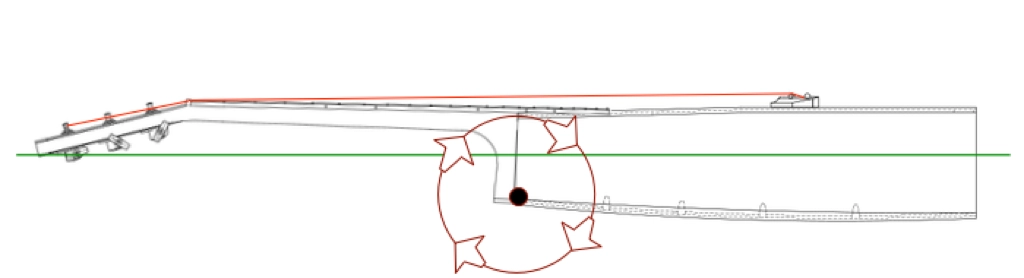

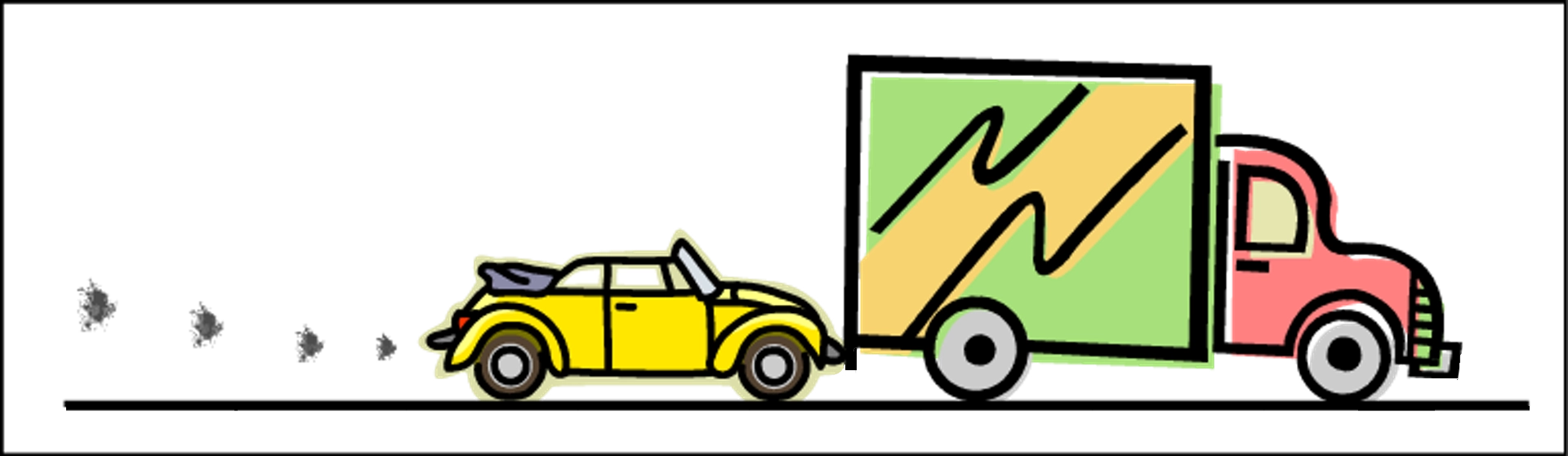

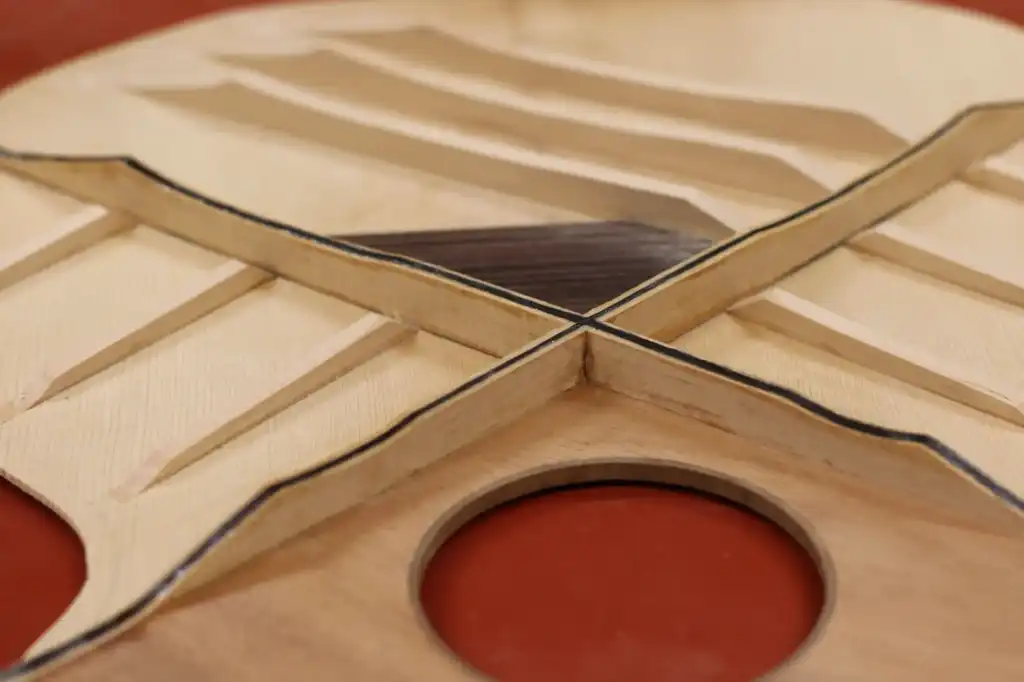

The neck block (and everything attached to it) may suddenly rotate forward in response to a sudden change in load and/or a sudden failure in structural support. In the worst-case scenario, the soundboard will split along one or both sides of the fretboard extension, and literally shear off into the soundhole. Stop to consider that, on all center soundhole, X-braced guitars there is NOTHING in front of the fretboard extension except 12.5 square inches of missing soundboard! It is into the abyss of the soundhole that the neck block, the neck attached to the neck block (including the fretboard), and the section of the soundboard glued to the neck block all seemingly seek to plunge.

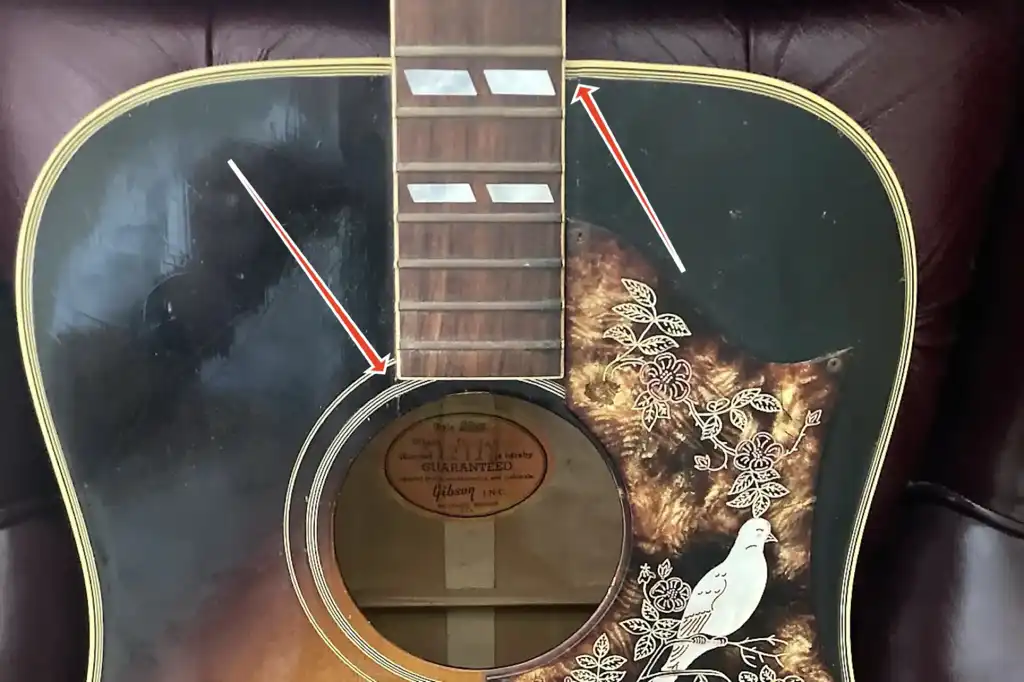

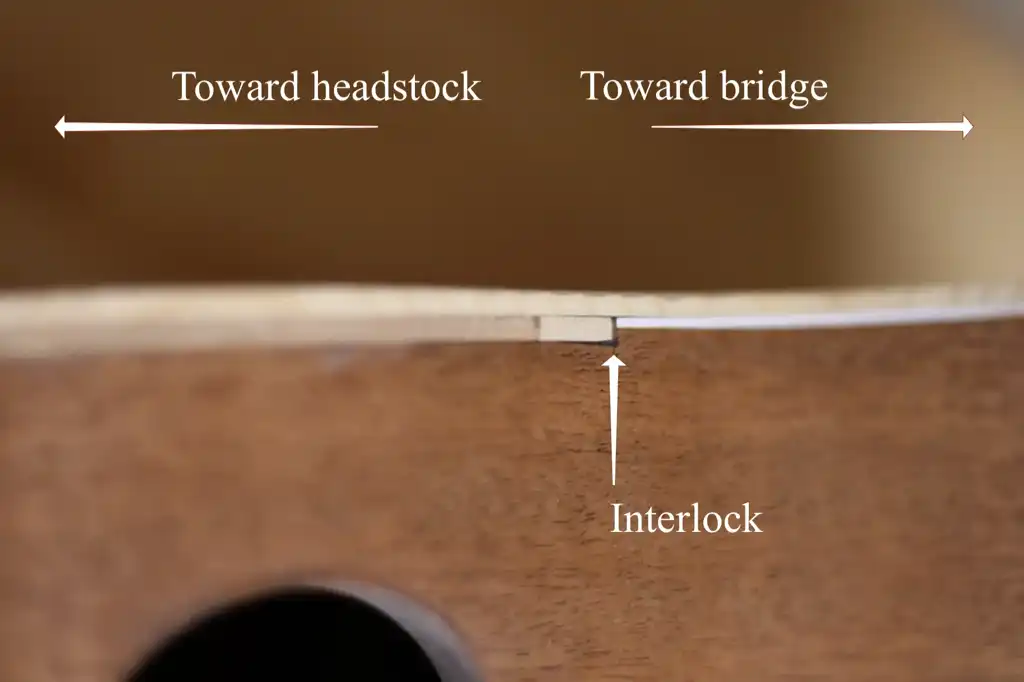

After a sudden shift forward of the neck block, there may be a spring back to the original position which may, in turn, leave little visual evidence of the trauma. If there is a split in the soundboard (or two splits, one on either side of the fretboard extension), this may or may not be apparent, depending on the severity of the shift.

NOTE: If you have ever wondered why you cannot keep a given guitar in tune, one that should stay in tune (as every other possible reason has been eliminated), look (diligently) for a split.

In addition to a crack in the wood, there may be a visible mis-alignment at the soundhole, as you can clearly see in the photos, below. Sometimes such splits are not readily noticeable and other times there is such significant forward movement that not only is the soundboard jutting out into the soundhole, but the neck has moved forward into the body, curling the binding in with it. Using the tuning machine heads you can tighten and loosen the strings and watch the deformation occur in real time. Severe damage, such as you see in the photos of the 6-string guitars, below, are an example of sudden, catastrophic failure.