Destructive Forces

A 5-gallon bucket of water weighs just under 42 lbs (2-1/4 kg). Imagine lifting one 42 lb bucket with one hand and lifting a second 42 lb bucket with the other hand. You are holding the equivalent of the tension applied by a set of nylon strings between a Classical guitar's bridge and its headstock.

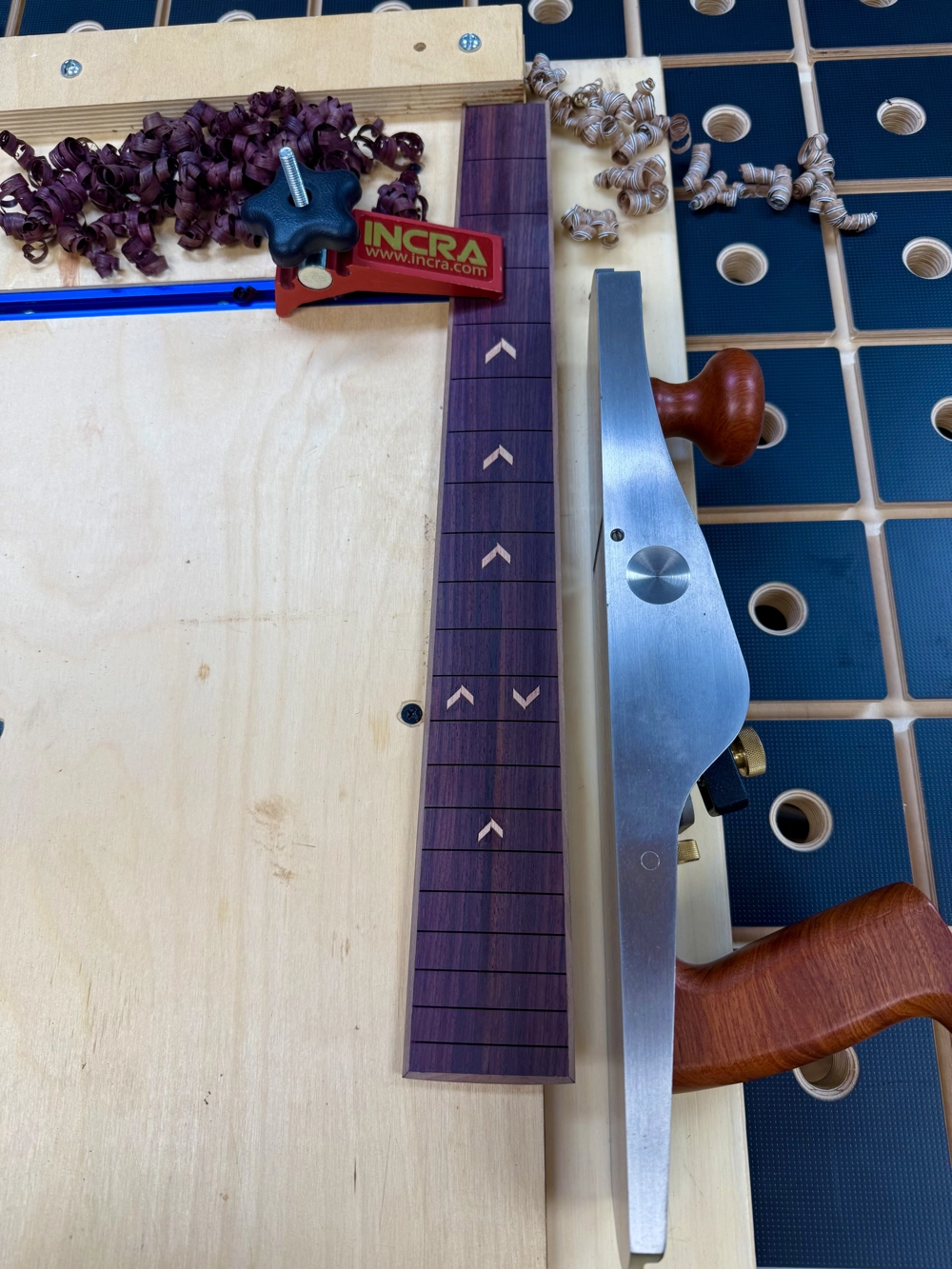

Now double that load, as you would if you replaced those nylon strings with a set of light gauge steel strings. It is suddenly necessary to reinforce the guitar against the added tension, or suffer the consequences. This is traditionally accomplished by installing a truss rod in the guitar's neck and replacing those delicate fan braces with a substantial X-brace pattern with its additional "tonebars" and "finger braces".

NOTE: Please don't kid yourselves: The purpose of this design is first and foremost to prevent deformation and catastrophe. Only then can we talk about sound and tone and esoteric stuff like that.

Increase that load again and you are in 12 string territory *, where wooden guitars only survive such loads with careful structural reinforcement.

* = D'Addario EJ86 bajo sexto -> 308 lbs tension!

This load upon the acoustic guitar introduces three issues that plague guitar maker and guitar owner, alike:

Body Flexion / Neck Block Shift

Conventional/traditional guitar construction addresses these issues in the following way:

To mitigate forward neck bow, install a dual-action steel truss rod.

To mitigate body flexion / neck block shift, hope for the best. When damage occurs, cleat the split(s) in the soundboard and reset the neck. Call the whole thing "stabilized".

To mitigate bridge rotation ... wait! Don't mitigate bridge rotation. Since you can't add any more bracing to the soundboard without negatively impacting the sound, market bridge rotation as a feature. When bellying occurs, if it's mild, reset the neck. If it's bad, send the guitar off for repairs.

When attempting to speak generally regarding the overall sound of an acoustic guitar, it is important to bear in mind that there isn't any one particular sound associated with the modern acoustic guitar, evidenced by the plethora of acoustic guitar offerings. It is, therefore, rather disingenuous to argue on behalf of something that doesn't exist (not that people won't do it, anyway). But all those different-sounding guitars definitely do share something in common: the sound they make is largely the after-the-fact result of the construction methods used to prevent deformation/implosion. Thinking that the generated sound is the direct result of centuries of careful innovation, and that the structure is just a catalyst, like some non-participating bystander, is a bit naïve. If we can overcome the structural requirement traditionally imposed upon the wooden plate we claim is responsible for the sound generation, perhaps we can pursue a new experience. Perhaps we will hear a new voice. Who knows until we try, right?

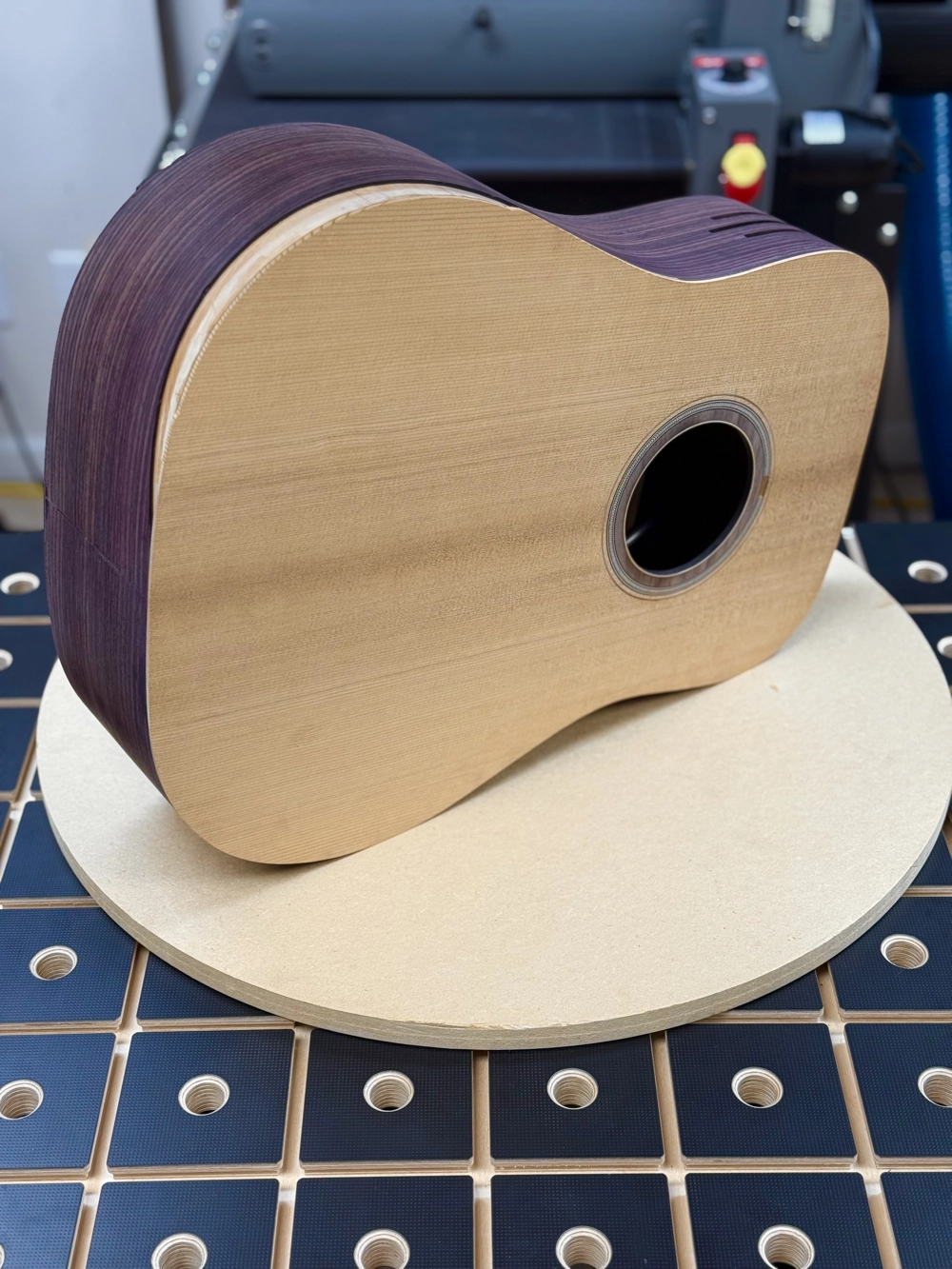

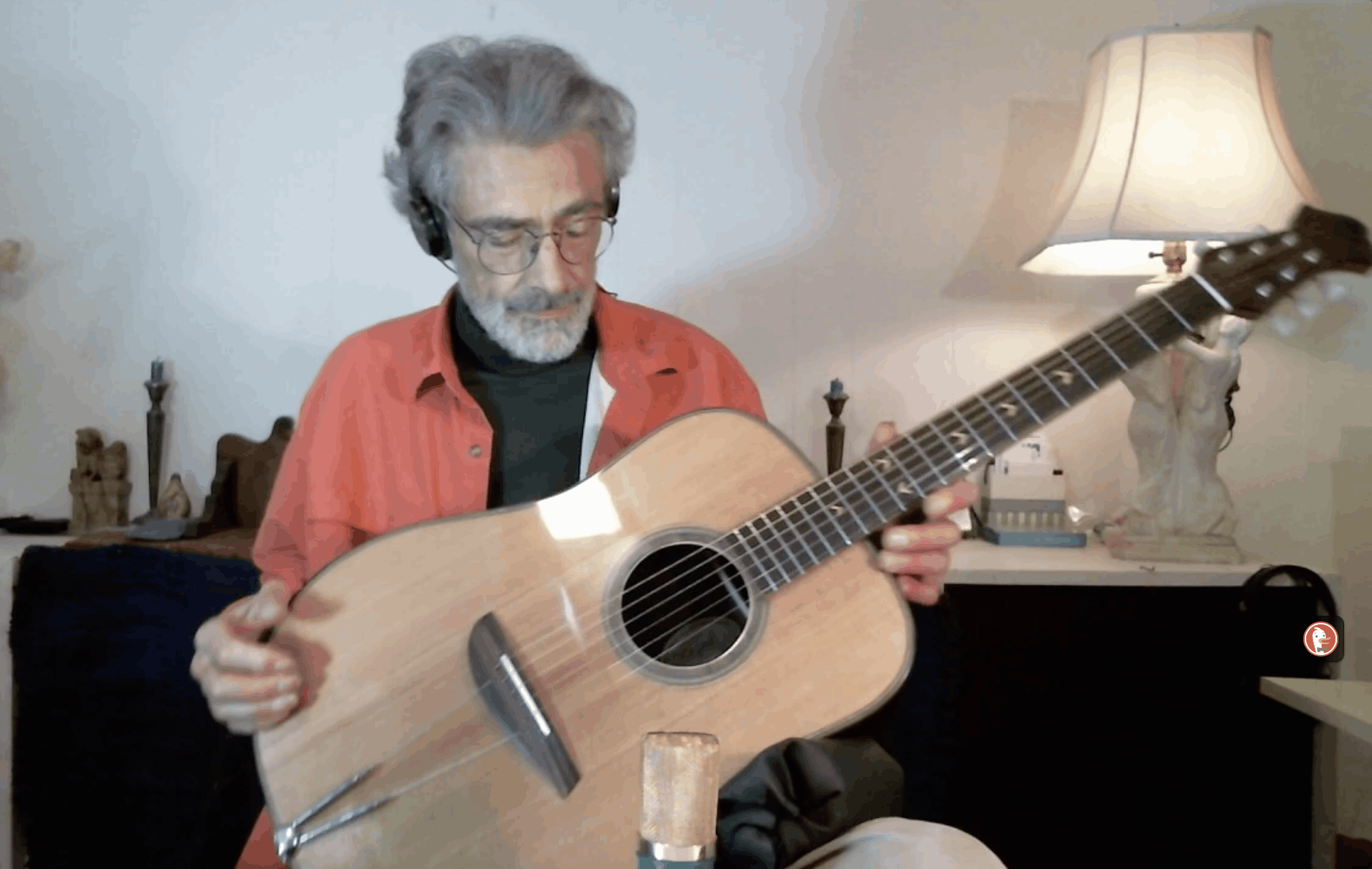

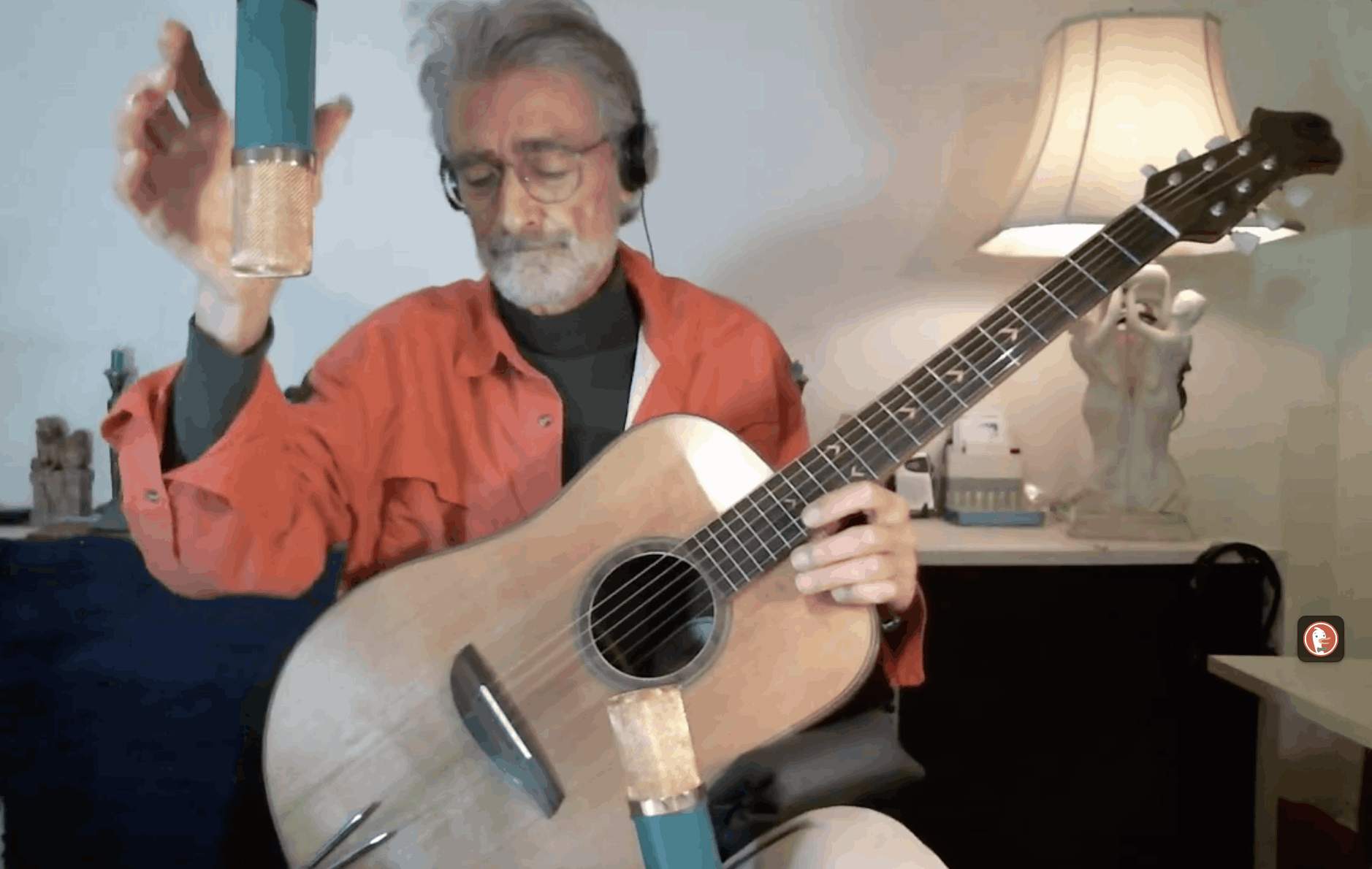

While constructing this conventional-looking acoustic guitar I am attempting to address all three issues identified above while producing a more responsive steel string guitar in the process. I will go into detail for each of the three issues, below, but here is the short version:

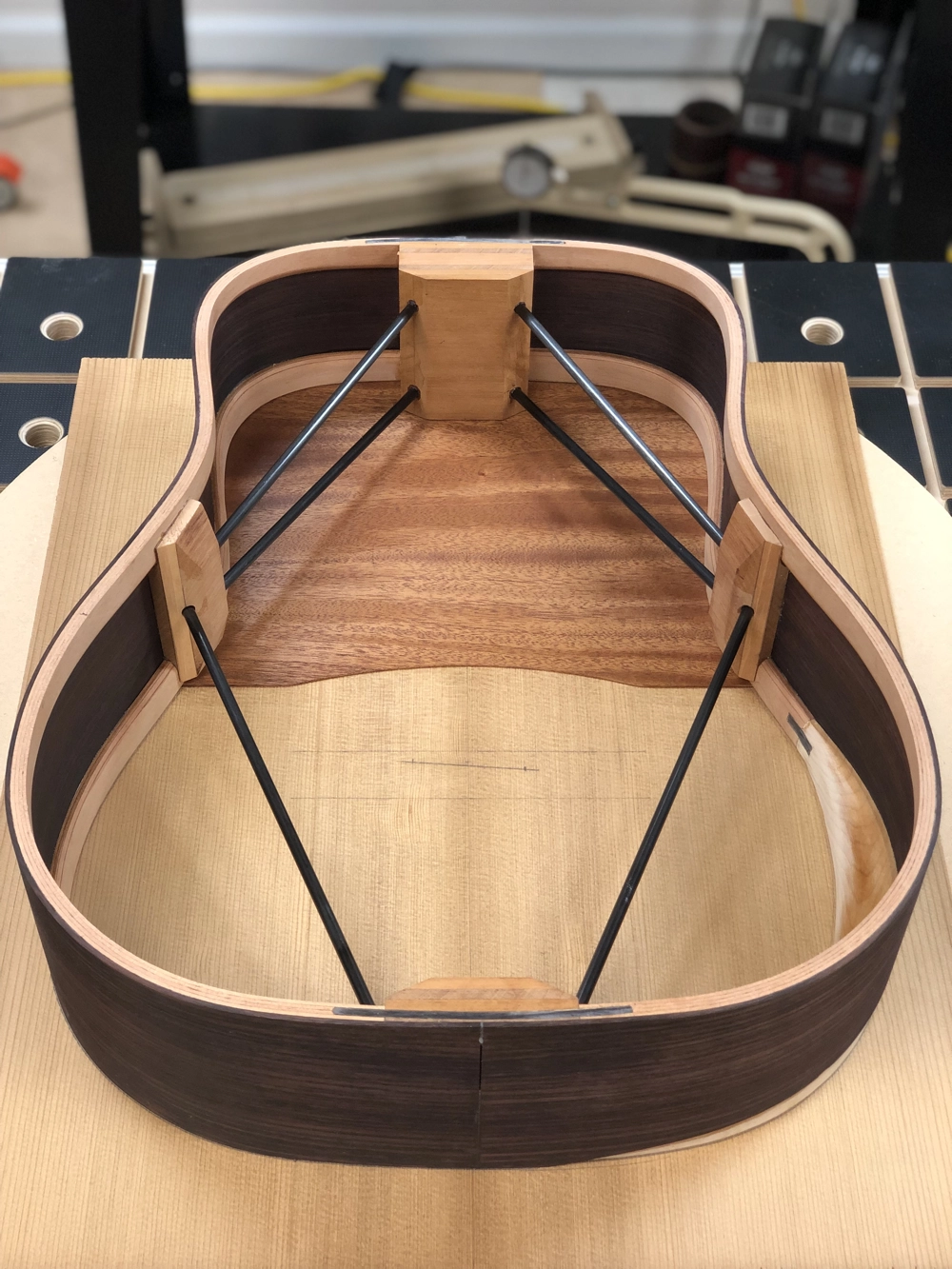

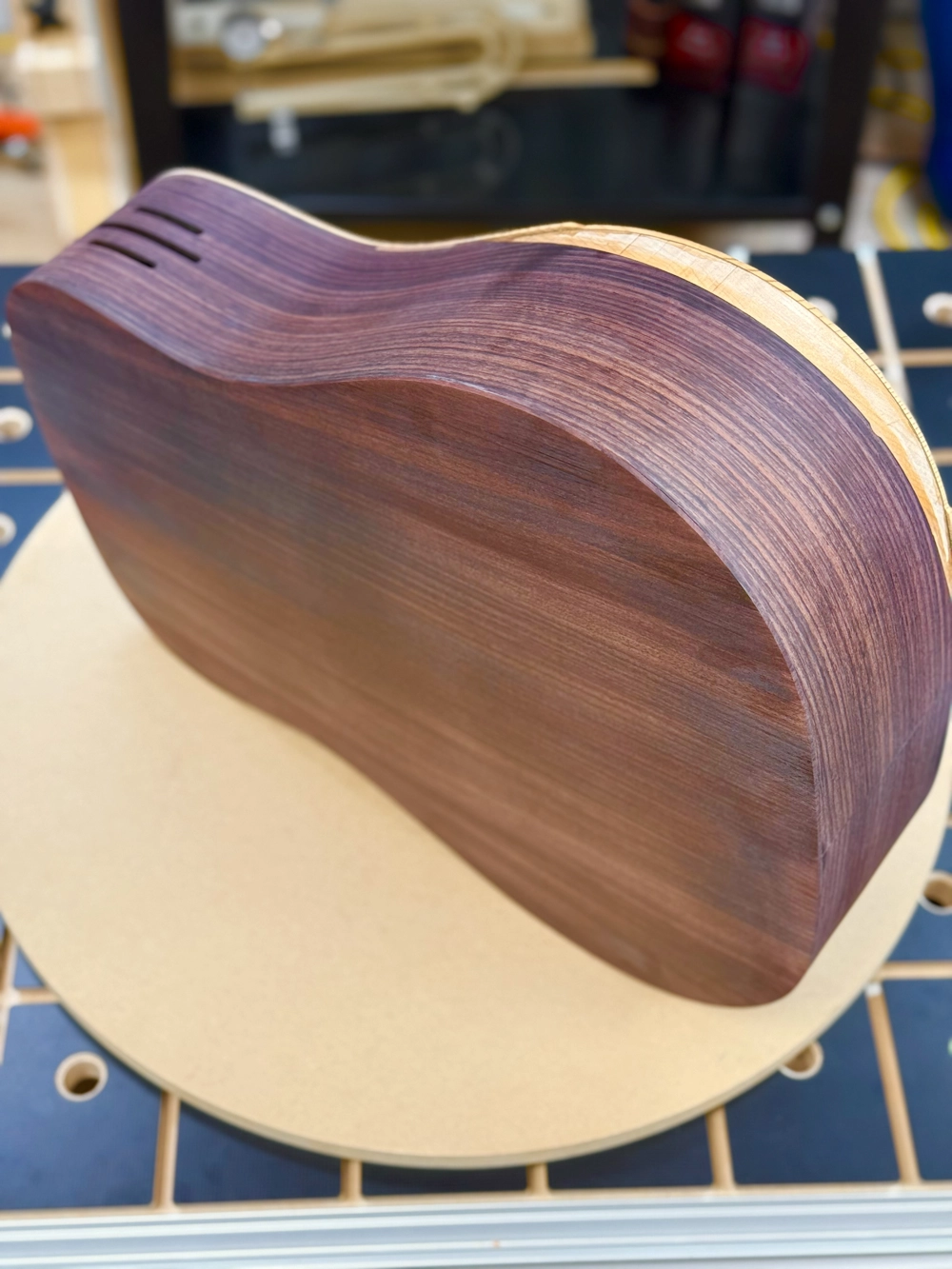

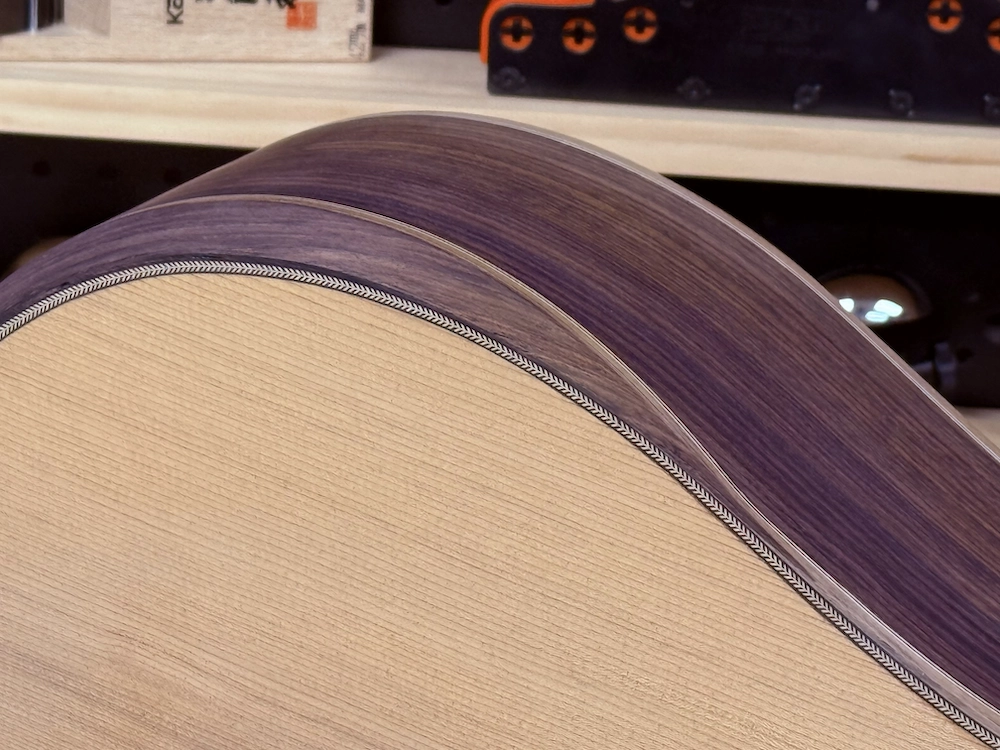

To mitigate body flexion - neck block shift: I will stiffen the body using laminated linings and carbon fiber rods, as well as add a hardwood veneer to the upper bout of the soundboard and lock the whole thing into the (stiffened) sides. Laminated sides are also a viable option, though this guitar will use solid sides.

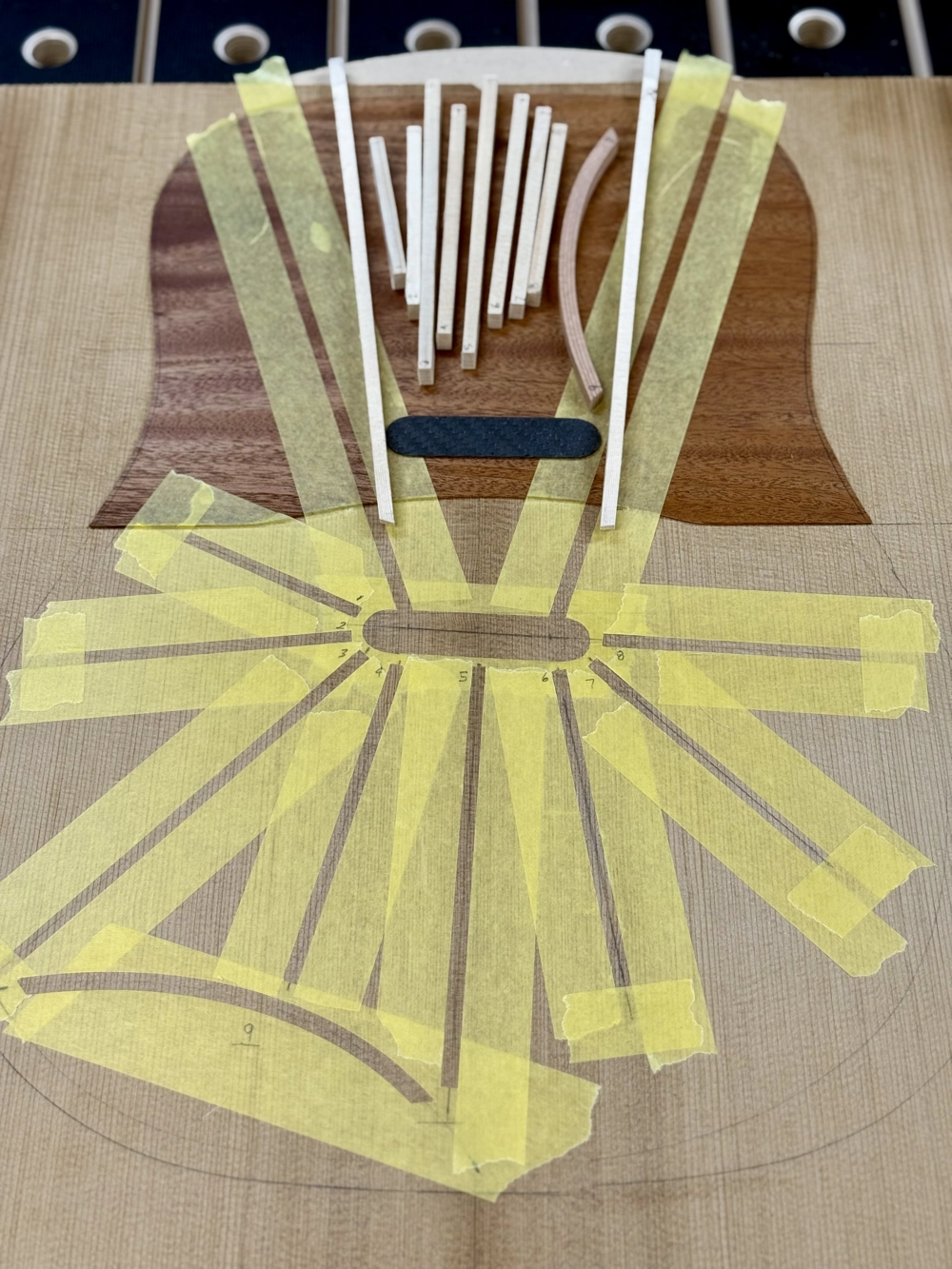

Taking this instrument a step farther, all due to the support afforded me by the TurboTail, I have opted to abandon the X-brace pattern altogether in favor of a very lightly-braced radial pattern. Without the TurboTail, such a lightly-braced soundboard would not support steel strings, at least, not for very long.

NOTE: Regarding bracing patterns such as X, V, Fan, Falcate, Radial, and more ... I am not even convinced any bracing is required with the TurboTail, but I have to start somewhere.

If, for some reason, I would later choose to remove the TurboTail from the Turbo-D, I could always install nylon strings.

Hmm, a nylon string Dreadnought ... has one ever been built? What might I call it? A class-nought or classic-nought?

How about a dread-assical?

Let's look at the infamous three issues more closely and see how I am addressing them in this guitar.