Why Consider an Alternative to a Truss Rod?

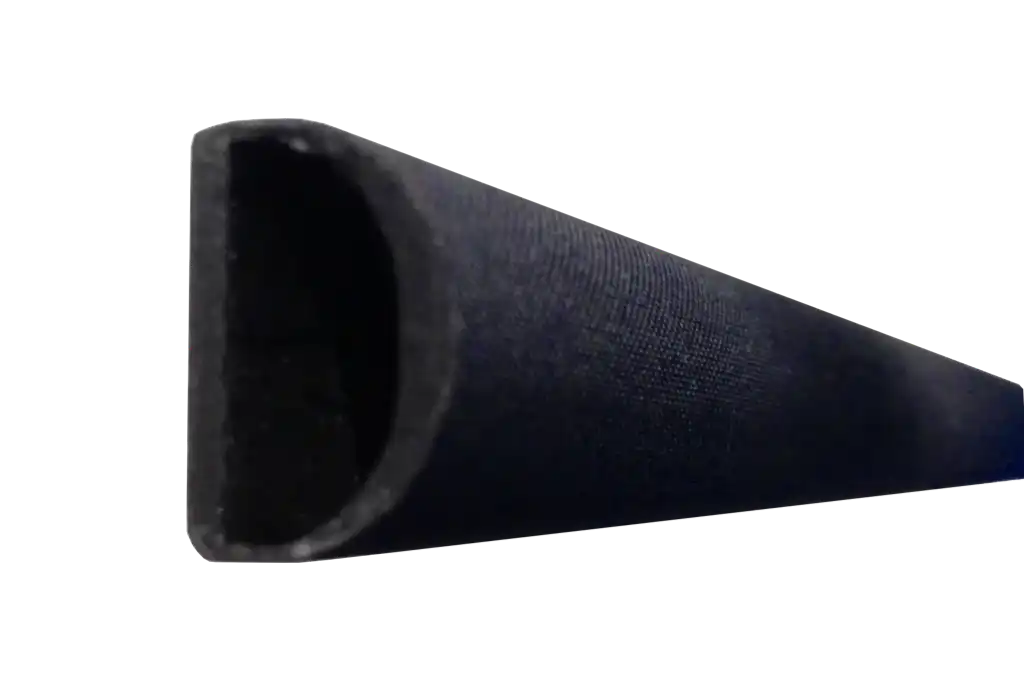

A growing contingent of builders and players have become convinced that these steel fixtures (square tubes, T-bars, I-beams, U-channels, compression rods, single-action truss rods, dual-action truss rods, etc.) have no place inside their instrument necks and are actually detrimental to both the playability and the sound of their guitars. They contend that the weight of the added steel does not make for an optimally balanced neck, and the metal fixture may have/has a negative impact on the overall tone.

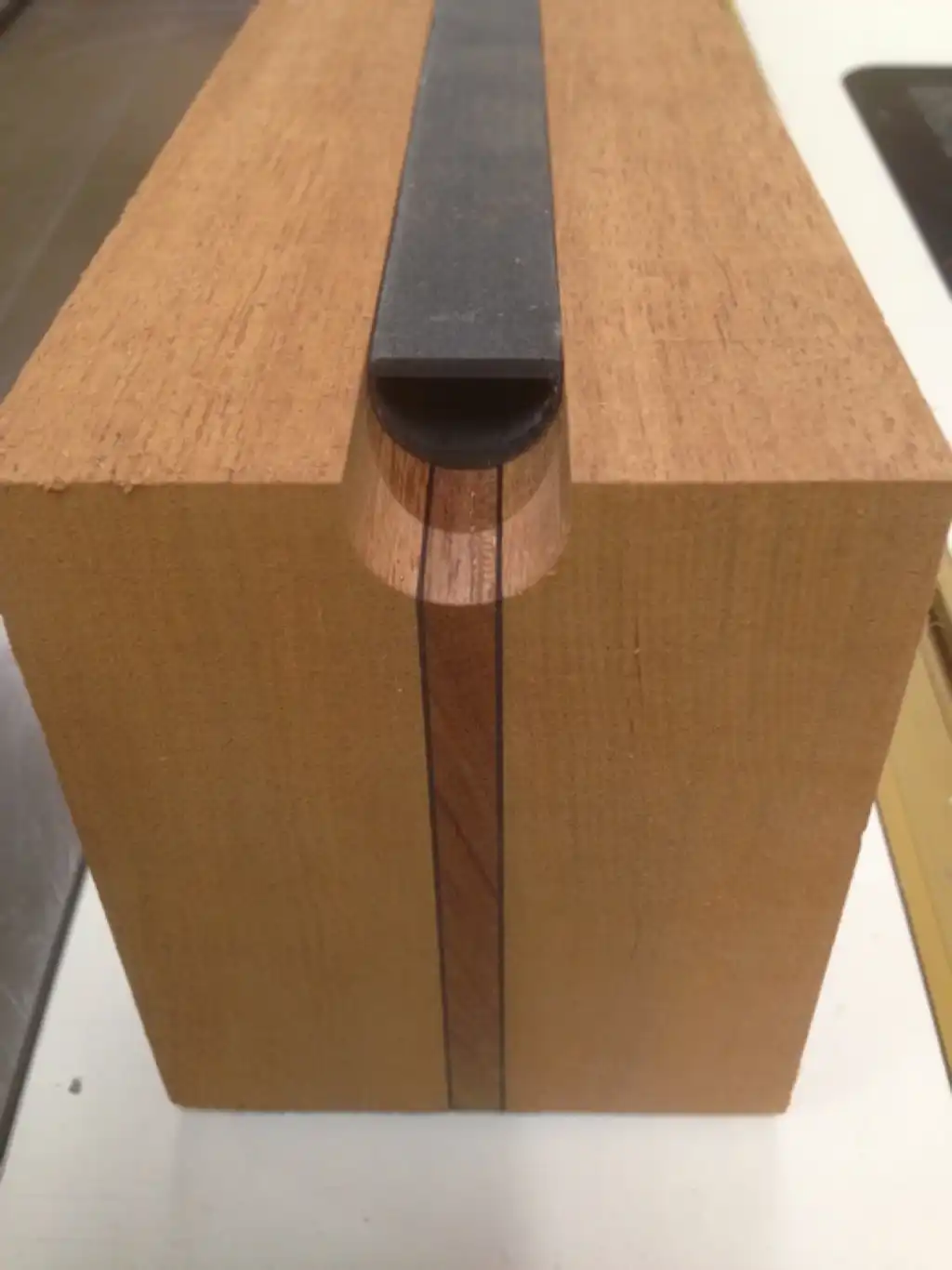

CONSIDER: The goal of acoustic guitar construction is to transmit as much string energy to the soundboard as possible, with the least amount of damping. On guitars that have a dual-action truss rod, an entire section of the structural frame supporting the length of the strings (the neck, directly beneath the fretboard), which could have been tasked with transmission of energy, has been removed to accommodate a potentially damping-inducing mechanical tool.

The first patented truss rod was intended to counter the pull of the strings by closing the distance between the fretboard and the now elevated string path, elevated as a direct result of the inability to construct a wooden neck having sufficient stiffness to resist the increased tension of the steel strings, introduced in 1900.

In the application for that patent, filed in 1921, a benefit was identified, that being the ability to "... to use wood which has not been heretofore considered satisfactory for the manufacture of necks, on account of its not having sufficient strength and rigidity, and further, great care in selecting stock is not necessary."

Wooden necks became slimmer and lighter, as the factor of neck stiffness, once a hallmark of lutherie as evidenced by centuries of the intentional symbiosis between wooden necks and catgut strings, was summarily replaced with the newfound mechanical ability to force a neck, any neck, into shape with the twist of a hex key.

Significant strides have been made since that point in guitar design history when the adjustable truss was introduced and the requirement to build sufficiently strong and rigid necks was eliminated. Builders at that time didn't share in the wealth of knowledge we now possess regarding the design and construction of the guitar. Had they had access to the technology of carbon fiber, I think the truss rod story might have turned out differently.

Regardless, a truss rod is not necessary in my guitars.